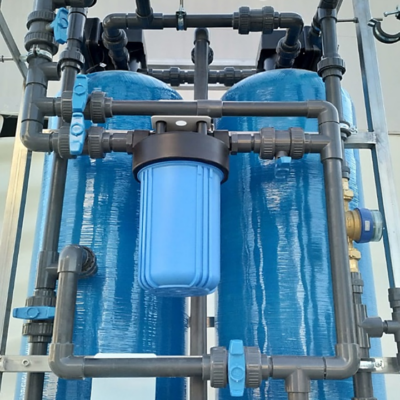

Zeobox™

Inomhusvattenrening

Zeobox™ är en revolutionerande lösning för att producera hälsosamt dricksvatten på allmänna platser samtidigt som miljön skyddas. Den renar vatten kontinuerligt och eliminerar alla patogener och föroreningar utan användning av kemikalier. Zeobox™ erbjuder olika alternativ för användare att välja mellan, inklusive olika vattenmängder, leverans av varmt eller kallt vatten och betalning via kort eller mobilappar. Maskinen är utrustad med en 27-tums LCD-skärm och en självständig förstärkningspump och råvattentank som är lämplig för områden med instabilt vattentryck i rörsystemet. Med fjärrövervakning och kontroll, installationservice, hjälp och underhåll är Zeobox™ ett lättanvänt, automatiskt och självrengörande system som ger rent dricksvatten till alla.

| Nominell kapacitet | 200 personer/timme | |