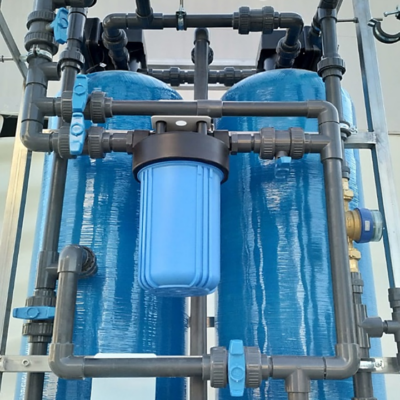

Zeobox™

Indoor water purification

Zeobox™ is a revolutionary solution for producing healthy drinking water in public locations while protecting the environment. It purifies water continuously and eliminates all pathogens and pollutants without the use of any chemicals. Zeobox™ offers a variety of options for users to choose from, including different water volumes, hot or cold water delivery, and payment through cards or mobile apps. The machine is equipped with a 27-inch LCD screen and a self-contained booster pump and raw water tank suitable for areas with unstable water pressure in the pipe network. With remote monitoring and control, installation service, assistance, and maintenance, Zeobox™ is an easy-to-use, automatic, and self-cleaning system that provides purified drinking water to everyone.

| Nominal capacity: | 200 persons/hour | |